From the perspective of a sales person of cutting tools products; everyone would have faced this question from the customer “What is the tool life of your product?” And the answer could be `X’, `Y’ or `Z’ meters and so on. Today we will discuss this important question on tool life.

What is tool life?

In a simple language the tool life is a duration from start of the cut to wear or failure of the tool. Tool life is directly affecting the machining cost per component and hence it is an important question from the perspective of the cutting tool user. That’s why most of the customers asks this question to cutting tools supplier / sales person. However, it is not so simple as it seems to be. One should study, analyze and take appropriate actions in order to achieve optimum tool life.

How to measure the tool life?

As said above; tool life is a duration or time period. So, what exactly is it? Tool life should be considered as REAL CONTACT TIME between the cutting tool and the workpiece during which metal (or non-metal) is being cut. Any idle time; when cutting action is not carried out, should not be considered in the tool life. The right method to measure the tool life is a unit of time such as 10 Minutes, 60 Minutes, 2 Hours and so on. Then many people convert it into the unit of length such as meters. But, the true method to measure the tool life is time. Alternatively you can also measure it in terms of MRR; i.e. total volume of metal removed by the tool before it worn out / failed.

Factors affecting the tool life

It is not so simple to just say that the life of a tool will be `X’ minutes or `Y’ meters. There are several factors or working conditions affecting the life of a tool. In no particular order; some of these factors are:

- Material being cut

- Operation to be carried out

- Machine being used

- Selection of a cutting tool.

- Proper selection of tool material & cutting-edge geometries

- Use of coolant, its concentration, pressure and volume

- Tool Holding

- Work Holding

- Cutting Speed

- Feed Rate

- Depth of cut

- Selection of tool path

- Desired dimensions and tolerances

- Special Tools

Now we will briefly address each of the above points and how do they affect the tool life.

1. Material being cuT

The first thing one should know is which material to be cut. It helps us to choose the best available cutting tool material. Also, just to know the material grade or group (e.g. SS316, EN24, GG30, SAE8620, OR Alloyed Steels, Stainless Steels, Cast Irons, High Temperature Alloys etc.) of the material being cut is not enough. We should know as much details as possible that includes; material condition such as rolled, cast, forged or heat treated. Material skin and hardness also plays vital role in tool life.

Many times, alloying elements in the material also have significant effect in tool life e.g., Silicon content in Aluminum alloys. So, if you know what is being cut better, you would be able to choose the right tools and adjust the cutting parameters and achieve better tool life.

2. Operation to be carried ouT

As such, in most cases it will be decided by the component drawing itself. However, study of operations to be carried out will allow us to choose to machining set-ups, tools, operational sequences or altering the method.

3. Machine Being Used

Machine is the key investment for anyone who carry out machining processes. To get the best out of a cutting tool’s potential; machine plays vital role. You have to consider machine rigidity, power & torque as well as size of the spindle before dive into selection of tool and cutting parameters. Older, Low powered or less rigid machine shouldn’t be used for heavy metal removing applications, otherwise tool life will be badly affected.

Here, I wish to give you an illustration that how machine is playing its role in the tool life. Now, consider that you have a component that need to make a hole of Ø70mm X 400mm Long. You have a Vertical Machining Center with BT40 Spindle

without coolant through spindle and 7.5/11 KW Power. So, here you can not use larger dia. Drill and Length to diameter ratio will go up for smaller diameter tools that leads to vibrations and consequently reduces the tool life. Also, external coolant can’t help to keep the cutting zone cool enough and chip evacuation could be a big problem Instead of these specifications; if you have BT50 Spindle Taper with Coolant through Spindle and high torque, high power spindle motor, the hole can be drilled quickly with improved tool life.

4. Selection of a Cutting Tool

Right tool selection for an application is the key to success. It includes style / type of the tool, chip-breaker, tool material, coating etc. Proper study of the application would lead us to choose the best tool available in the market and then it will perform well in the given application & cutting parameters.

As a thumb rule; strongest possible tool should be applied in context to the application. For example, in an application of plain turning, negative insert is the preferred choice. Even in the negative inserts; the shape of the Insert plays vital role. Round shape is the strongest and if your application permits, you should go for Round shape Insert. Other shapes from stronger to weaker includes CN… (other corners), SN…, CN…. (regular corners), WN…., TN…., DN….,VN…. and YN…

Similarly in round shank tools you should consider the Length (mostly flute length) / Diameter ratio. It should not be more than 3 unless it is the demand of the application. That means flute length should not be more than 3 times the diameter of the tool. Un-necessary overhang will reduce the tool life.

5. Proper selection of tool material & cutting-edge geometries

Selection of Cutting tool materials for your application is vital. In modern metalworking industry tool material is available for almost any application. When we are talking about cutting tool material; it includes basic material as well as the surface treatments such as coating. Development of cutting tool material has a long journey of thousands of years from ordinary stone to precious stone (Diamond).

Cutting-edge geometries play very important role in curling or breaking the chips and thereby affecting the tool life. Cutting-edge Geometries includes chip-breakers as well as edge preparation like T-land, chamfer, honing etc. In combination with the tool material, cutting-edge geometries performs well and that is how the tools are designed.

6. Use of coolant, its concentration, pressure and volume

Coolant, an important factor and directly affecting the tool life. Now a days most cutting tool manufacturers offers tools to be used without coolant i.e. dry machining. However, it is not the case for all applications. You should (rather you must) use coolant for machining of high temperature alloys and work hardening materials. Heat is a killer of tool life and high heat is generated at the cutting point while machining of such materials. Coolant plays vital role in keeping the cutting zone cool as well as evacuating the chips from the cutting area.

There are varieties of coolant available such as neat cutting oil, water soluble cutting oils, mist coolants, air coolant, paste type (such as tapping paste) etc. Water soluble cutting oil is the widely used coolant. Here, it is recommended that you should consult the cutting oil supplier and maintain coolant concentration ratio; it is very important while cutting exotic materials. Coolant pressure and flow volume also improve tool life; especially in operation like drilling. Make sure that coolant is directed to the point of cutting.

7. Tool Holding

Tool Holders – The Hidden Gem; normally neglected while judging the tool life. But, tool holders are one of the main contributors to tool life; especially in case of rotating tools. Low investment – High impact is the key formula one should consider before selecting the tool holders. Take an example; if you are using Ø16mm Solid Carbide End Mill and hold it on a regular ER32 Collet Chuck. And you are happy with the tool life as well.

Now, the twist is here; just go for a accurate and more rigid tool holder such as Hydrogrip Chuck or Shrinkfit Chuck. With these tools, the clamping force will be uniform around the surface of the tool shank so you will get better gripping strength and superior concentricity. Tool run-out will also be improved compared to ER Collet system. All these factors will help to improve the tool life.

Now, have a look at the Investment part. Say, you are paying 4 times the cost of a regular ER Collet chuck for a hydrogrip chuck and your tool life is improved by just 5%. Please do calculate the cost of the tool holder, cost of the tool & it’s annual consumption and the improvement in tool life; you will observe that the Return on Investment is within few months. Normally it is not visible straight away and that’s why I call it The Hidden Gem.

8. Work Holding

Similar to Tool Holding; work holding also has it’s role in obtaining to better tool life. It is applicable to both stationary and rotating work piece. Have a look at a scenario of Workpiece Holding on Turning Center. You wish to hold a rectangular or square workpiece on a turning center; what you should do? The simple answer is you should use four jaws or two jaws chuck. Making a temporary fixture to be hold on three jaw chuck or face plate is not a good idea. Designing special jaws suitable to your component could also work well. Rigid holding of the workpiece will certainly pays back in terms of cutting time and the tool life.

9. Cutting Speed

Cutting Speed (or cutting velocity) – the killer of tool life. Amongst the three key cutting parameters i.e. Speed, Feed rate and Depth of Cut; Cutting Speed (Vc) dominates 60% – 70% contribution to tool wear! So, what to do? Always use lowest cutting speed? No, it is not like that. Consult your tooling supplier or study their Catalogue and get the recommended cutting speed for your application. Then consider all other aspects as mentioned in this article and optimize the cutting speed. It has direct impact on the tool life and machining time and it is dependent on Cutting tool material as well as the material being machined.

10. Feed Rate

The most important factor for productivity and moderate effect on tool life. Optimized feed rate can significantly enhance the tool life. It is advisable to take full advantage of high feed rate on rigid machines. Higher feed rate also causes vibrations, so choose the feed rate considering the machining conditions. Also, if you observe rapid crater wear; it means your feed rate is high and it need to be reduced. Feed rate contributes 20% – 30% on the tool life.

11. Depth of Cut

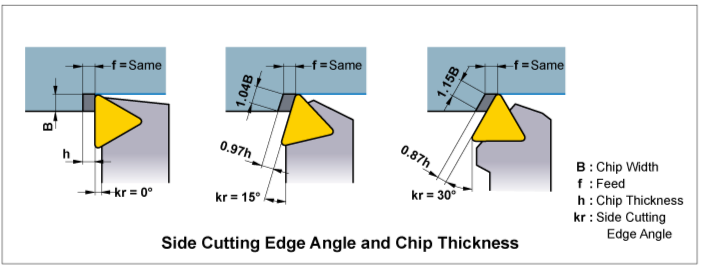

Normally it depends upon the raw condition and finished dimensions of the part to be manufactured. However, you can use larger depth of cuts in heavy metal removal applications. It has minor effect of the tool life as it’s engagement is directly proportional to the length of the cutting edge. For example; if you are applying CNMG120408 for turning with a depth of cut 3mm; approximately 3mm cutting edge length will be used. Now, if you are applying SNMG 120408 (with 45° approach angle), then 6mm length will be used.

Please refer above image that shows relation between cutting edge angle, cutting edge engagement (i.e. chip width), chip thickness and feed rate.

12. Selection of Tool Path

Sometimes it happens that a little bit modification in tool path helps to improve tool life. It is mainly applicable in Turning, Milling, Grooving and Threading applications. Here, I would like to explain by an illustration that how the tool path can contribute to the tool life. If you are carrying out turning operation on Stainless Steels, High-Temperature Alloys, Materials prone to Work-hardening or Hardened materials (above 55 HRc) and taking uniform depth of cuts; then the most common wear pattern would be Notching at the depth of cut line. If you overcome this depth of cut notching, then your tool will last longer. In milling operation, down milling (climb milling) is preferred over up milling (conventional milling).

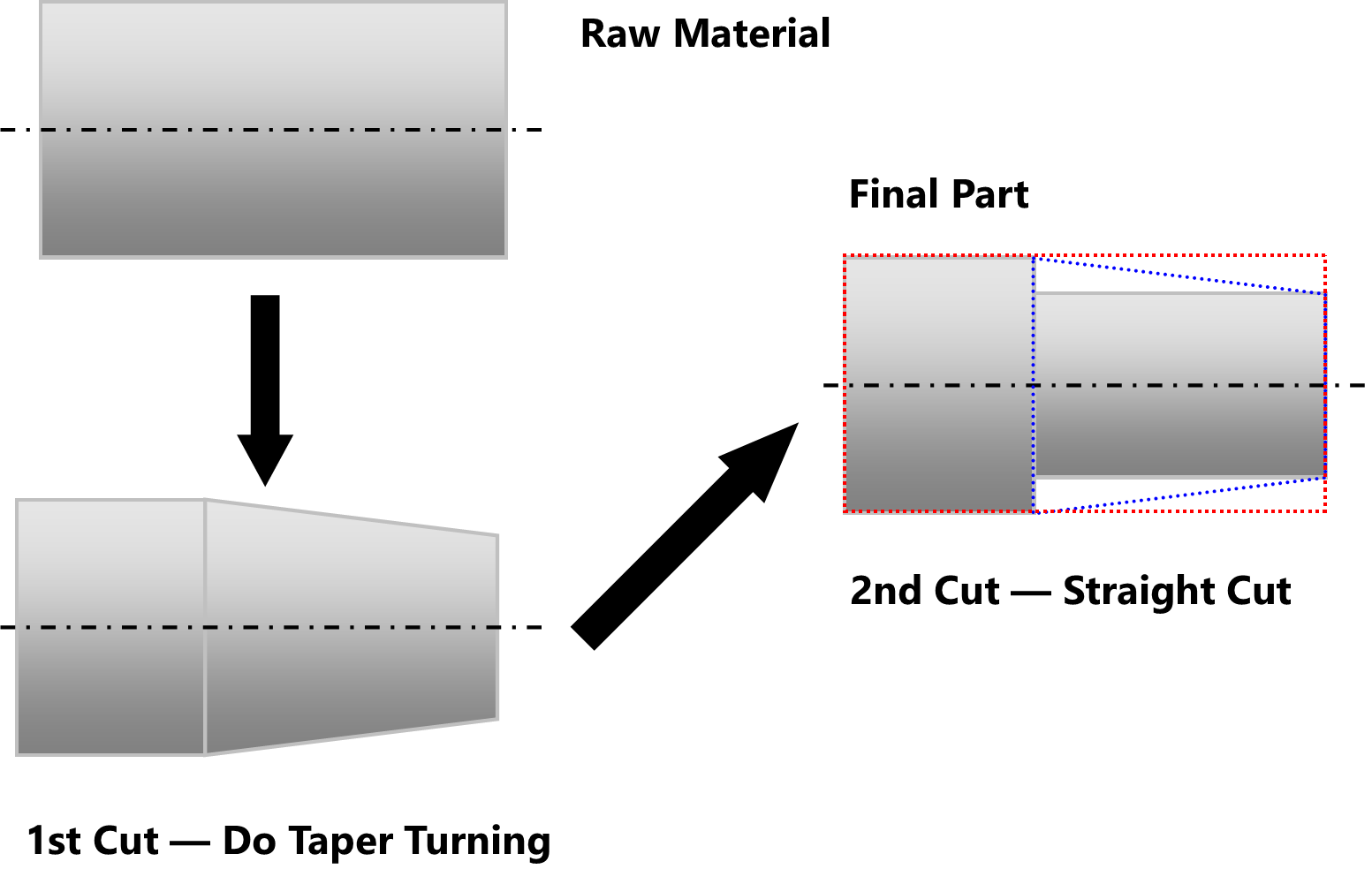

Now, how to overcome it? Very simple, just change the tool path as shown in the image below:

Refer the above diagram and see the sequence of turning operation.

- First cut is Taper is turning. Here, the cut starts from maximum depth and gradually decreases at zero depth of cut towards the end.

- Second cut is Straight cut; but actually, it removes the material left by the first cut. So, the second cut starts from zero depth and gradually increasing at maximum depth towards the end.

- Doing so, the depth of cut line is constantly changing and hence chip pressure and heat zone also varies that prolong the formation of notching and extend the tool life.

- There is another way of using different depths of cut. For example; If you wish to remove 6mm material radially in turning operation, then you should take 4mm & 2mm or 3.5mm and 2.5mm depths of cut instead of taking three cuts of 2mm or two cuts of 3mm.

13. Desired Dimensions and Tolerances

Apparently, it has no direct effect on the tool life. However, it help us to choose the right parameters that would contribute the tool life. You can use higher feed rate or depth of cuts when the part being produced is having open tolerances and surface roughness requirement is not so critical.

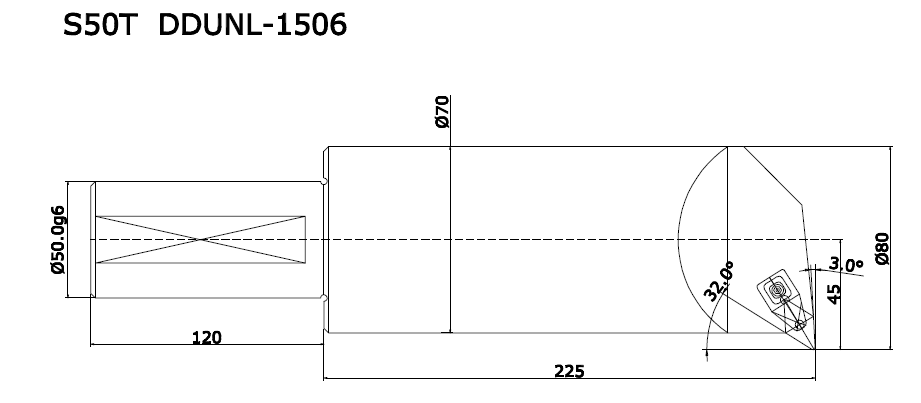

14. Special Tools

It also has minimal direct effect on tool life. But, in some cases it may be useful to go for special tools where you can notice on the improvement on the tool life. I would like to highlight one such application where you can use special tools; even for standard applications. The application is internal turning (boring) on CNC Lathes. For instance, your requirement is to create large bore of Ø250mm and depth 220mm. Your machine turret can accommodate Ø50mm Boring Bar. What you should do? As per my opinion, you should go with a special boring bar as shown below:

We have supplied such special boring bars to customers and observed that the tool life is improved. If you use Ø50mm boring bar; the overhang would be more than 4 Times the diameter and in combination with axial & radial forces the Ø50mm boring bar may tend to deflect and generates vibrations as well. So, applying special tools may certainly help to enhance tool life.

Conclusion

To conclude this article, I would like to highlight following points and request you to maintain them as long as they are feasible for your application.

- Use rigid machine, tool holding & work holding

- Optimize Cutting Parameters

- Effectively use coolant. (Sometimes dry machining may also be helpful)

- Wherever feasible, use special tools.

- CONTROL HEAT, TOOL DEFLECTION & VIBRATIONS as long as possible.

0 Comments